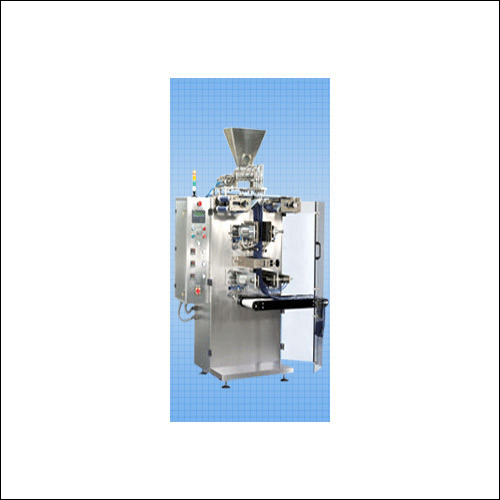

Multi Track Sachet Packer

We have established ourselves as a renowned supplier of Multi Track Sachet Packer PNR-150. The offered product is developed by experienced professionals using latest technology and quality approved component sourced from the genuine vendors of the industry. These machines are examined on various parameters of quality, by the quality experts before delivering it to the customers. All these machines are highly applauded by the customers for their features like robust construction, performance, easy installation, durability and least maintenance. It is widely used for auger filler, cream filler, cup filler and liquid filler and can be availed by us in customized range and reasonable market prices.

Specifications

- Filling range varies from 0.5gm-20 gm

- It gives output up to 100 pack per minute in 2 lane format

- It gives output up to 200 pack per minute in 4 lane format

- Size of the packs range from 30mm-75mm in width

- Pack/sachet size ranges from 50mm-140mm in length

- Max. reel dia. 400 mm on 76 m/m core

Sachet Packer

Sachet Packer PNR-100, A Vertical Form Fill Seal Automatic Machine for producing most types of Powder & Granular Sachets

General Information

A Vertical Form, fill and Seal Machine for producing 3/4 side sealed sachet, handling all types of free flowing powders / granules. The machine speed is infinitely controlled from 0-95 cycles/minute Single reel film laminate stock reel feed. Max. reel dia. 400mm on 76mm core. Product dosing by cup filler. All parts in contact with product are made of high quality stainless steel. Sealing dies gear operated with complete pressure and temperature control on sachet seal area.

Product Range

Powders, Granules, Spices, Soup Mixes, Detergents, Pharmaceuticals and Agricultural powders, Tea, Coffee

Filling Range

0.5 gm up to 50 gms., Depending upon bulk density of products.

Output

From 20 packs per min up to 95 pack per min,Depending on product flow characteristics and pack size.

Pack Size

Width from 30mm to 100mm, Length from 50 mm to 140mm. Extended size on request.

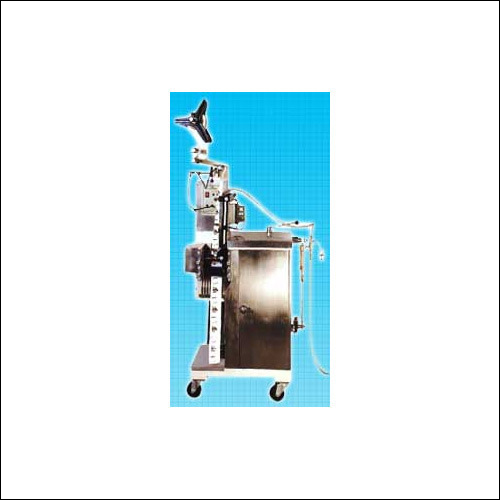

Sachet Packer Liquid Filler

General Information

A Vertical Form Fill Seal Machine for producing 3/4 side sealed sachets handling all types of free flowing powders / granules.The machine speed is infinitely controlled from 0 - 95 cycles / minute. Single reel film laminate stock reel feed. Max. reel dia. 400 m/m on 76 m/m core Product dosing by cup filler. All parts in contact with the product are high quality stainless steel. Sealing dies gear operated. With complete pressure and temperature control on sachet seal area.

Product Range

Shampoo, Hair Oil, Lotion, Liquid Detergent, Alcohol, Sauces and other liquids.

Filling Range

1 ml up to 60 ml

Output

From 20 to 95 pack per min, depending on product flow characteristics and pack size

Pack Size

Width from 30mm to 100mm, Length from 50 mm to 140mm.

Powder & Granules Sachet Packer

Our firm provides Powder & Granular Sachet Packer that are made with high grade materials which are procured from the best vendors in the industry who are highly reliable.

Benefits attached with the products are:

- Product level control

- Perforator between sachets

- Product elevator system

- Over printing attachment

- Emboss coding

- Auger filler

- Tear cut device

- Gas flushing

- Batching device

- Take off Conveyor

- Liquid filling attachment

Packet data available to our clients are:

- Centralized lubrication system

- Uses any heat sealable laminate or film

- Pack widths adjustable from 50 mm to 200 mm (On request)

- 3/4 side seals with crimp pattern/line pattern

- Change parts such as collars, cups, gears, needed for size change

- Pack widths adjustable from 30 mm to 160 mm (On request)

Electrical

| Motor | 0.5 HP, 3 Phase 415 V AC driven through VFD, or 0.5 HP, single phase 220V AC, 50-60 Hz |

| Heaters | 300 w X 4pcs cartridge type |

| Temperature Controller | Temperature Controller with FEK thermocouple |

| Fully Automatic Photo Control |

Dimensions & Weight

| Floor Area | 750 mm X 600 mm |

| Height | 1750 mm |

| Net Weight | 300 Kgs approx. |

| Gross Weight | 370 kg when packed in one case |

Sachet Packer With Auger Filler

We are prominent manufacturers and suppliers of a wide range of vertical form, fill and seal machine known as Sachet Packer With Auger Filler PNR 200 that are highly reliable and easy to operate. The installation of the machine is very easy and we ensure that our service provider client installs and specifies all the details of the product to the client in an elaborated form so as to get maximum client satisfaction.

Its specifications are:

- Tool kit and Operators Manual

- Comprehensive push button

- Cut off blades

- Photo cell print registration

- Fully controllable die pressure

- Manufactured in stainless steel

Pack Data clients can avail from us are:

- Centre seal with crimp pattern / line pattern

- Uses any heat sealable laminate or film

- Centralized lubrication system

- Change parts such as collar, cups, gears needed for size change

- Telescopic, adjustable cup filler provided to take up variations in product bulk density

Electrical

| Motor | 0.5 HP, 3 Phase 415 V AC driven through VFD, or 0.5 HP, single phase 220V AC, 50-60 Hz |

| Heaters | 300 w X 4pcs cartridge type |

| Temperature Controller | Temperature Controller with FEK thermocouple |

| Fully Automatic Photo Control |

Dimensions & Weight

| Floor Area | 750 mm X 600 mm |

| Height | 1750 mm |

| Net Weight | 380 Kgs approx |

| Gross Weight | 450 kg when packed in one case |

Cream & Paste Sachet Packer

We have in store for our clients a wide range of Sachet Packer PNR-100 (Cream & Paste Sachets) that are used to seal products such as Mayonnaise, Grease, Petroleum Jelly, Sauce, Ketchup, Lotion, Cream, Balm and Toothpaste. With high and new technology we provide this machine with a very high speed for proper and timely sealing of the products.

Extra options we make available with this are Take off Conveyor, batching device, over-printing attachment, Infeed product elevator system Liquid filling attachment, perforator between satchets, tear-cut device and emboss coding.

Its specifications are:

- Pack Size Width from 25mm to 100mm, Length from 50 mm to 150mm. Extended size on request

- Filling Range 0.5 gm up to 30 gms., Depending upon bulk density of products. Higher capacities on request

- Output Up to 50 packs per minute, Depending on product flow characteristics and pack size

Pack Data our clients can avail are:

- Uses any heat sealable laminate or film

- Centralized lubrication system

- 3/4 side seals with crimp pattern/line pattern

- Change parts such as collars, gears needed for size change

- Pack widths adjustable from 50 mm to 200 mm (On request)

- Pack widths adjustable from 25 mm to 160 mm (On request)

Electrical

| Motor | 0.5 HP, 3 Phase 415 V AC driven through VFD, or 0.5 HP, single phase 220V AC, 50-60 Hz |

| Heaters | 300 w X 4pcs cartridge type |

| Temperature Controller | Temperature Controller with FEK thermocouple |

| Fully Automatic Photo Control | 1 HP, 440 V AC 3 Phase |

Dimensions & Weight

| Floor Area | 750 mm X 600 mm |

| Height | 2000 mm |

| Net Weight | 300 Kgs approx |

| Gross Weight | 370 kg when packed in one case |

Multi Track Sachet Packer

We are engaged in providing our clients a wide range of Vertical Form-Fill-Seal Machine that are highly durable. OurMulti Track Sachet Packer is used for preparing powder, granular, liquid and cream sachet. We ensure high quality standards for our products and make sure that the materials we procure are from the best vendors in the industry.

Our Product Range is as follows:

- Liquid Filler : Shampoo, Alcohol, Water, etc

- Cup Filler : Free Flowing Powders, Pharmaceutical Powders,etc

- Cream Filler : Ketchup, Sauce, Cream, Chocolate Paste

- Auger Filler : Non-Free Flowing Powders

Extra benefits we provide with the product are tear cut device, emboss coding, perforator between sachets, over-printing attachment, takeoff conveyor and a batching device.

The specification are:

- Output:

In 2 lane format up to 100 per minute

In 4 lane format up to 200 per minute

Depending on product flow property and pack size - Pack Size:

Width from 30mm to 75mm, Length from 50 mm to 140mm - Filling Range :

0.5 gm up to 20 gms., Depending upon bulk density

Electrical

| Motor | 1 HP, 3 phase 415 V AC, 50 Hz with VFD controls. |

| Heaters | 300 w |

| Temperature Controller | PID Temperature Controller |

| PLC controls with HMI | |

| Fully Automatic Photo Control |

Dimensions & Weight

| Floor Area | 1000 mm X 1000 mm |

| Height | 2000 mm |

| Net Weight | 300 Kgs approx |

| Gross Weight | 600 kg when packed in one case |

Multi Track Sachet Packing Machine

We are proud manufactures of a mesmerizing product that provides with a 3-side sealed sachet using a vertical form fill and seal technique. Our machine is so well designed that it accepts almost all types of laminated films that too up to a maximum limit of 500 gauge. The product is made using high grade stainless steel that is procure from some of the best vendors in the industry. It is also manufactured in our unit as per the specifications of our valued clients. The product range we pack using Liquid Filler are toothpaste, creams, shampoo, Chocolate Paste, Conditioner, Oils, Grease and almost any viscous or free flowing products. Products sealed using powder filler are yeast, spices, soup mix, tea and coffee. Extra options we make available for our clients are over-printing attachment batching device, takeoff conveyor, emboss coding, tear cut device and perforator between sachets.

The specifications are mentioned:

- Pack Size Width from 25 mm to 100 mm, Length from 50 mm to 250 mm

- Filling Range From: 1 gm to 50 gms. Depending upon bulk density of product

- Output Up to: 200 packs per minute with 4 tracks, i.e.,50 packs per minute,Depending on product flow properties and pack size

Sachet Packer Auger & Cup Filler

Our store offers our clients an innovative product Sachet Packer PNR-200 Auger & Cup Filler that is used for producing most types of Granular Sachet and Powder with Central Seal Format. We provide packaging for auger fillers like Spices, Powders, Soup Mixes, Pharmaceutical and Agricultural Granules. Our Cup Filler range includes Pharmaceutical and Agricultural Powders / Granules, Tea, Coffee, Detergents, Snack Foods such as Farsans and Namkins. The product is made with high quality materials so as to ensure maximum durability of the product.

Its specifications are:

- Pack Size Width 35mm to 120mm or 80mm to 150mm. Length 50mm to 120mm or 90mm to 240mm

- Filling Range 0.5 gm to 25 gms or From 25 gms to 100 gms. Depending upon bulk density of product

- Output 20 to 70 packs per min depending on product flow properties and pack size

Sachet Packer Liquid Filler

We have in our range a vertical form of fill seal machine that is named as Sachet Packer PNR-100 Liquid Filler. The product is made with high quality stainless steel that make the product strong and sturdy. The sealing dies of the machine is gear operated that provides complete pressure and temperature control for a proper packaging. Product Range that the machine is used for sealing are Hair Oil, Lotion, Shampoo, Alcohol, Sauces, Liquid Detergent and other liquids.

Its technical specifications are listed below:

- Pack Size Length from 50 mm to 140mm, Width from 30mm to 100mm

- Filling Range 1 ml up to 60 ml

- Output From 20 to 95 pack per min, depending on product flow characteristics and pack size